| Main page – Polish armour » tanks » 7TP » part I – Polish artillery – Steel Panthers – what's new |  | ||

| © Michal Derela, 2015 | Updated: 25. 02. 2024 | ||

| Main page – Polish armour » tanks » 7TP » part I – Polish artillery – Steel Panthers – what's new |  | ||

| © Michal Derela, 2015 | Updated: 25. 02. 2024 | ||

Part I: Development, production, description

Part II: Service & evaluation

|

| 7TP trials at Błędów Desert in Poland |

Development – Production – "9TP" tank – Description – Specifications – Modelling | Part II: Service

The 7TP was the only genuine tank produced in Poland before World War II, not counting tankettes, which hardly can be regarded as tanks. It was also the most combatworthy Polish armoured vehicle at a time of the German invasion in 1939, and one of icons of pre-war Polish Army. The 7TP was the most advanced of all Vickers 6-Ton tank derivates in the world, and can be considered a Polish design, being a compilation of several foreign licences and own inventions, a far-going development of the basic tank. Despite it was not the most modern tank in 1939, but it kept the world's standard of a light tank, when this class constituted a mainstay of armoured forces worldwide, and could be a match for any enemy vehicle at that time.

This article is an attempt to sum up most recent knowledge about the 7TP tank. Despite its popularity in Poland, some areas still wait for a thorough complete research. On this occasion we also fix several errors, that can be found in new Western (and even some Polish) publications. Note: links in a text without an underline lead to Wikipedia articles.

After World War I and regaining of independence, a basic tank of Polish Army was the French Renault FT, possessed in numbers that placed Poland among the leading European armoured powers. However, in the 1920s, its limitations became obvious, such as low speed and ineffective armament. At that time, there started works upon equipping the Army with a more modern tank, that could be manufactured in Poland. The experience of the Polish-Soviet War of 1919-1920 proved, that a tank should be a weapon of manoeuvre warfare, and therefore Poland decided to focus on relatively fast and well armed light tanks instead of slow and heavily armoured infantry tanks. However, Polish designers did not have sufficient experience – as demonstrated by the tank design contest announced in April 1926, which led to the creation of the unsuccessful WB 10 prototype. Therefore, the only rational solution was to purchase a modern license abroad as a basis for further development. Assessing Polish capabilities, it should be remembered, that Poland was partitioned for over a century before World War I, and (unlike in neighboring Czechoslovakia), none of occupants was eager to place its machine or automotive industry there. As a result, it had relatively weak industrial base at the moment of regaining independence. Moreover, after the war, priorities were to defend borders and rebuild and unify the country, with a tight budget. Additional negative factors, apart from poorly developed industry and limited design teams, were the attempts of the Sanation authorities to monopolize automotive production by state-owned producers, as well as the suppression of the automotive market by car taxes in 1931.

Poland had traditional military ties with France, but new Renault M26/27 and NC designs, purchased for testing in 1929, were not found satisfactory. The Poles also tried to buy an example of a widely advertised Christie's wheel-and-track tank in 1930, but Walter Christie refused to deliver the ordered machine (more in 10TP tank article). Poland eventually decided to buy the British light tank Vickers Mark E, better known as Vickers 6-Ton tank, which was one of the most modern tanks in the world at the outbreak of the 1920s and 1930s. It should be remembered that in the early 1930s the number of tank designs available commercially abroad was very limited and many successful later competitors (such as Czech and Swedish tanks) had not yet been built. Initially, the Poles attempted to purchase only parts of the running gear and drive system of a Vickers tank, with the intention of developing its own design bypassing the purchase of a license, but Vickers-Armstrongs set the condition of purchasing one or several entire tanks and licenses.It should be noted, that after designing several own moderately successful tanks, also the Soviets relied upon the Vickers 6-Ton licence, creating the most numerous tank in the world before World War II – the T-26.

In September 1931, Poland bought 38 twin-turret tanks Vickers Mk.E Type A, with a licence to manufacture them for own needs. Next, 22 of them were rebuilt to single-turret Type B, with a short-barrel 47 mm gun (more on Vickers E in Poland page). The tank was considered a successful design, although it revealed several faults as well, mainly an overheating engine and thin armour. Therefore, unlike the USSR, Poland did not start a production of the Vickers Mk. E, but at the end of 1932, Polish designers started working upon its improvement. The work was carried by the Armoured Weapons Construction Bureau (BK Br. Panc.) of the Military Engineer Research Institute (WIBI) in Warsaw. The chief designer was Aleksander Fabrykowski, and the project was under a supervision of Rudolf Gundlach. The designers also cooperated with the Studies Bureau of a future manufacturer – PZInż (Państwowe Zakłady Inżynierii – State Engineering Works). The new design was initially known as the VAU 33, but soon the official designation was established as the 7TP (7-tonowy polski - 7-Ton, Polish), even though the tank's weight exceeded 7 tons from a beginning.

The weakest point of the Vickers Six-ton was its 90 HP air-cooled petrol engine Armstrong-Siddeley, which was prone to overheating. As a result of the assessment made in Poland, the license was purchased without an engine (unlike the license for the USSR). At an early stage of development it was decided to replace it with a more powerful and reliable water-cooled Saurer diesel engine, manufactured in Poland under Swiss licence. In this way, the 7TP became the first tank powered by a diesel engine produced in series in Europe, and one of the first in the world (at a similar time, such engines were introduced to Japanese tanks). Its main advantages were greater torque and flexibility, ensuring better traction and less frequent need to change gears (as assessed in the first test report: "in the field, due to the greater acceleration of the engine, it overcomes all natural obstacles more easily... Driving on dirt roads took place on fourth gear"). Contrary to popular belief, the slightly less ignitable fuel and lower fuel consumption were of less practical importance – on the other hand, diesel oil was less widespread in Poland and therefore less available in the field.

The choice of the diesel engine was in fact accidental, as the weakness of the industrial base meant that it was the only engine with an adequate power produced in Poland at that time. However, the engine used was far from being optimal. Its main disadvantage was, that it was very heavy, even though in Poland the weight of the original Saurer BLD engine was reduced and its power was increased from 90 HP to 110 HP by using direct fuel injection, creating the VBLDb variant. The new upright inline engine and its water radiators, replacing horizontal inline air-cooled engine, required a high rear compartment, which was the most obvious visual difference compared to the Vickers Mk.E and T-26 family. The desire to balance the heavier engine made possible slight thickening of the armour in the frontal part, and it was of better quality than the Vickers armour (surface-hardened plates up to 17 mm thick instead of homogeneous plates up to 13 mm). Other improvements included a reinforced suspension and a new Polish gearbox. The tank was also to be equipped with a modern anti-tank gun, although its selection was made only at the end of 1935. Initially, twin-turret tanks were temporarily produced, equipped with turrets armed with machine guns taken from rearmed Vickers tanks. A minor visual difference from the front were new, smaller headlights on fenders, on a central stand instead of a fork mounting.

The VAU 33 (or V.A.U. 33) stood for Vickers-Armstrong-Ursus, or according to other version, Vickers-Armstrong Ulepszony (improved), 33 for the year. The designation 7TP was derived from Vickers Mk.E, which was often called in Polish documents just a '6-ton tank' (czołg 6-tonowy), and later a '7-ton', or in short: 7T tank, which better corresponded with its actual weight. It is commonly accepted, that a letter P meant polski – Polish. The designation was often written as '7 T.P.' in original documents. Twin- and single-turret variants had no specific designations. In Western publications they are often marked with additional letters: "dw." or "jw.", which are abbreviations of Polish words: dwuwieżowy = twin-turret [approximate pronunciation: dvoo-vye-zhovy] and jednowieżowy = single-turret [yedno-vye-zhovy]. However, they were not a part of the name, and such abbreviations are not known in any Polish sources. They might be used for a sake of convenience only, but they should always be separated from the name by a space. The single-turret variant was however regarded a standard one, without a need of additional designations.

| |||

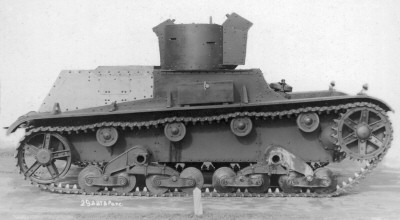

| The first 7TP prototype 1595 (it has an experimental welded rocker arm and non-standard toolboxes). | |||

| |||

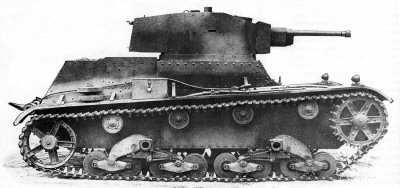

| The first serial tank 1597, wearing an old camouflage. It has non-standard vertical spare wheels. Lt. Stefan Kossobudzki is on the turret, a future commander of the wartime 1st Light Tank Battalion. | |||

| |||

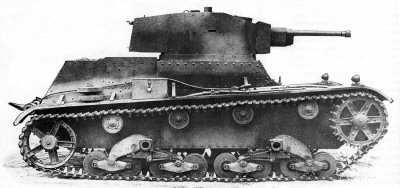

| A modified 7TP prototype, with an original Bofors turret. | |||

| |||

| Early production single-turret 7TP tank (note a low muffler). | |||

| |||

| Zmodyfikowany prototyp 7TP Smok, z oryginalną wieżą Boforsa. | |||

| |||

| Czołg 7TP wczesnej produkcji (widoczny nisko położony tłumik). | |||

| |||

| Czołg 7TP późnej produkcji (badany w ZSRR). | |||

| 7TP deliveries | |||

|---|---|---|---|

| Order year | Number ordered | Serial Nos. | Completion |

| 18 March 1935 | 22 | 1683-1704 | 4 in 1935, rest by summer 1936 (all twin-turret) |

| 7 February 1936 | 16 | 1705-1720 | spring 1937 (without armament - possibly 2 twin-turret) summer 1938 (completed - 14 single-turret, or all single-turret) |

| 1937 | 18 | 1721-1738 | summer 1938 (single-turret) |

| March(?) 1937 (extra order) | 49 | 1739-1764 1765-1787 | 16 in end of 1938, rest by May 1939 |

| 1938 | 16 | 1788-1803 | summer 1939 |

| 1939 | 32 | 1804-1814 | only 11 in September 1939 |

| total: 132 | = 22 (or 24) twin-turret = 110 (or 108) single-turret | ||

| Note: This table is based upon works of J. Magnuski, but there are questions as for its reliability, concerning peculiar orders of tanks, number of single- and twin-turret tanks and their serial numbers. | |||

|

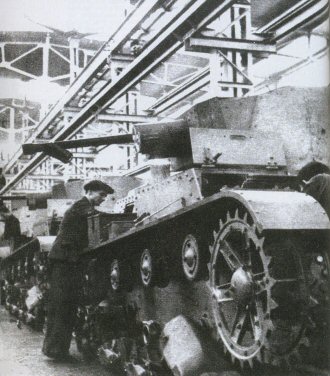

| Assembly of 7TP tanks in PZInż factory |

7TP tanks were assembled in PZInż F-1 (former Ursus) factory in Czechowice near Warsaw, which also manufactured their engines and transmissions (along with factory F-4), but most parts were delivered by numerous sub-contractors, chosen each time by bids. Armour plates for hulls were manufactured for different batches by steelworks: Pokój in Nowy Bytom, Baildon in Katowice, Batory in Hajduki Wielkie (all in Upper Silesia region), finally in 1939 also by new Zakłady Południowe (Southern Works) in Stalowa Wola (currently Huta Stalowa Wola). First 50 turrets were ordered from Ostrowieckie Works in Ostrowiec Świętokrzyski, which delivered armour plates, while the final assembly was in their subsidiary Steam Locomotive Works in Warsaw. The second batch of 58 turrets were ordered from Zieleniewski, Fitzner & Gamper factory in Kraków (their plates were made by Pokój steelworks in Nowy Bytom). There is no information where and when further turrets were ordered. Parts of turrets – main bearings were imported from Sweden (in the first series at least).

37 mm wz.37 guns were manufactured by SMPzA (Stowarzyszenie Mechaników Polskich z Ameryki – Association of Polish Mechanics from America) factory in Pruszków, which also made a towed variant. There were at least 111 tank guns made by September 1939, by two orders: 50 ordered in March 1937 and 61 ordered in April 1938 (one was mounted in a prototype 10TP tank). Only in April 1939 there was another order for 75 guns laid, but it is not clear, if any were completed. Machine guns were made by the FK (Fabryka Karabinów – Rifle Factory) in Warsaw.

Radios were made by State Tele- and Radiotechnical Works in Warsaw (according to other version by AVA in Warsaw), and optics by PZO (State Optical Works) in Warsaw. Tracks were made by Lilpop, Rau & Loewenstein in Warsaw.

Polish designers were aware of relatively poor protection of the 7TP, and planned its development. One tank no. 1766 was experimentally fitted with a new Saurer CT1D Diesel engine, which was to be produced in Poland as PZInż.155. In spite of slightly lower power output (100 hp at 1800 rpm), it was much lighter (around 600 kg instead of 850 kg). The tank was tested from May 1938, and the engine was considered as better, than the existing one. It was next tested in autumn 1938 with an extra weight to simulate heavier armour.

|

| BBT BP proposal for a strengthened 7TP. |

Two variants of an improved tank were proposed in April 1939. They are commonly known as 9TP tanks, although this designation almost certainly comes from a postwar literature, and they were known in original documents just as the "strengthened 7TP". More advanced proposal was developed by the Armoured Weapons Technical Research Bureau (BBT BP), led by Col. Patryk O'Brien de Lacy. The BBT BP proposed to use a new welded hull of a lower profile, with a slanted front plate of the combat compartment. The change in the hull shape was made possible due to replacing a Diesel engine with newly developed Polish 95 hp petrol engine PZInż.725 placed on the right side of the engine compartment (a drive shaft was also moved to the right side, so it would be less an obstacle for the crew). The engine had bigger fuel consumption, but its weight was to be only 345-370 kg. The armour was to be up to 30 mm – front and rear vertical plates, 25 mm – the front slanted plate and the driver's hatch, and 20 mm – sides and the turret. Thanks to removing cooling grates from an engine deck and replacing them with slots in sides, the tank would be more resistant to Molotov cocktails. The driver was to be equipped with a reversible periscope (or two of them, according to [1]). The tank retained weight of the 7TP - 9858 kg, with more even weight distribution on suspension sets. Maximum speed was estimated at 32-34 km/h. Overall height would be 1988 mm (less by 130 mm).

However, more conventional variant of the PZInż Studies Bureau (BS PZInż), worked by Edward Habich, was apparently chosen to be realized. Its hull shape and construction technology remained the same, as in the 7TP, only armour thickness increased from 17 mm to 40 mm in the hull front, from 17, 13 and 9 mm to 25, 20 and 13 mm respectively in the sides, and from 15 to 20 mm in the turret's sides and to 40 mm in its front. Weight also increased to 10 594 kg, so wider 320 mm tracks were proposed to decrease ground pressure from 0.71 to 0.585 kg/cm². An advantage would be equal weight distribution on front and rear suspension sets, while weight on the rear set would be even 10 kg less, than in 7TP (5279 kg in front and 5315 kg at the rear instead of 4540 kg and 5325 kg). Maximum speed was estimated at 29 km/h, which was an acceptable decrease, especially, that such was a practical speed of the original tank. An engine was to be lighter 100 hp PZInż.155 (Saurer CT1D) Diesel. Also a gearbox would be made of aluminium instead of cast iron. On the other side, there were carried studies on welded armour, which should decrease weight of an ordinary tank by 210 kg. It is worth to note, that the Soviets started to equip part of T-26 tanks with applique armour during the Winter War in 1940, increasing their weight even more (up to 12 t), without strengthening of the original engine.

An advantage of the BS PZInż development variant over the BBT BP one was, that it could get into production quicker, and used a licence-built engine instead of a new unproven one. Therefore, the head of the BBT BP proposed in April 1939 to build a mild steel prototype of his variant utilizing one of early prototypes, and to build one or two strengthened tanks of the PZInż variant, with new armour, within the 7TP batch that was under construction at that time, for further tests. The PZInż works itself proposed to manufacture newly ordered series of 50 tanks already in a strengthened variant, what would cause only slight delay. It is not known for sure, whether these proposals were accepted.

According to a common version, two prototypes of the PZInż variant of so-called 9TP were built by 27 July 1939, but there are no documents quoted, that would confirm it explicitly. It appears certainly a misinterpretation of available documents, and in fact there were no strengthened prototypes made, and the tests were carried with already existing no. 1766 tank with CT1D engine and a ballast, fitted with different transmissions during trials. As a result of tests in 27 July - 3 August 1939 period, a differential from the C7P tractor was found more suitable for strengthened tanks. The war spoilt plans of production of strengthened tanks. Some publications suggest, that 11 tanks 7TP of the newest production, received in September 1939, had strengthened armour, but it may only be regarded as ungrounded wishful thinking. It should be remembered, that they were the first tanks of the batch ordered in spring 1939, with already ordered armour. Publications also claim, that a new batch of 50 tanks ordered in 29 June 1939 was to have a strengthened armour, what seems plausible, though there are no documents quoted, apart from the PZInż proposal.

An early transitional model of the 7TP tank was twin-turret, armed with two water-cooled 7.92 mm wz.30 machine guns in turrets. The ammunition was around 6000 rounds (5940, considering typical 330-round belts?).

The main variant was single-turret, armed with 37 mm wz. 37 (Bofors) tank cannon, with a coaxial water-cooled 7.92 mm wz. 30 machine gun. Cannon ammunition was 80 rounds, mainly armour piercing with a tracer (AP-T). There were also used APHE rounds. It is not clear, if HE shells were used – they were available for towed guns and tested in tanks before the war, but a commander of the 2/2 Light Tank Battalion Cpt. Hajdenko claimed, that his tanks did not receive HE shells.

Only four rounds were stowed in the turret, to the right of the gun, however the crews reportedly stowed extra ammunition in the turret's rear niche in tanks without radio. The rest of ammunition was carried in the hull. Maximum rate of fire was 10 rounds per minute. Machine gun ammunition was 3960 rounds in 330-round belts, carried in 12 boxes. The MG was to the left side of the cannon, in a common mounting, and its barrel was protected with an armoured cylinder, as was the gun's recuperator.

Weapons had a telescopic sight wz.37 CA between the cannon and MG, and a periscope sight wz.37 CA on the left side of the roof. The periscope sight was based upon Zeiss TWZ-1, and could be used on the move, while the telescopic sight was used when stationery only. Both weapons were fired with a gunner's pedal, using a hand switch to choose between weapons. There were crank mechanisms for turret traverse and gun elevation, operated by the gunner.

The armour was made of rolled plates of face-hardened (cemented) armour (the hull) or homogenous armour (in the turret and horizontal plates), of differing thickness:

According to Soviet measurement, hull sides were 15 mm in the middle and 10 mm at the rear, roof was 11 mm in front part, turret roof was 15 mm apart from the hatch (9 mm). There might be some measurement error, although a difference in the turret's roof is significant.

| Comparative cross-section of Vickers E and 7TP (early) hull[9]. |

|

| Destroyed twin-turret 7TP, probably in Warsaw area. Noteworthy is a radio aerial base between turrets. Visible are fans on both sides of an engine. |

The tank was of a classic design, with a transmission compartment in front, combat compartment in the middle, and an engine compartment in the rear. The hull was made of rolled armour plates, bolted to a frame. The crew was three. The driver's seat was in front of the combat compartment, on the right side. Before the driver there was a large two-part hatch, with a simple periscope in a vision slot. Vision from the driver's seat in combat conditions was rather poor, and he had no means of side observation (just as in the original Vickers Mk.E).

Early twin-turret variant had two identical small one-man "dustbin" turrets, each with a hatch above. In this variant, the commander and gunner were sitting on fabric belts (the commander in the right turret). The turrets had significant box covers atop for magazines of 13.2 mm MGs, which were used in Vickers Mk.E tanks only.

The main production variant had a single conical two-men turret, offset to the left side. The commander had his station on the right side, and the gunner on the left side. The commander loaded the gun and pointed targets for the gunner, while the gunner searched for targets, aimed the gun and fired weapons (some publications erroneously claim, that the commander was a gunner, and the second crew member was a loader). There was a single hatch in the roof, opening forward, on the right side of the roof, above the commander. The commander had a reversible observation periscope wz.34 G in the hatch. There were also two simple fixed periscopes and two pistol ports in both side walls. A rear niche for a radio had an upward-opening hatch at the rear.

The reversible periscope was patented by R. Gundlach and enabled easy all-around observation for a commander. On a contrary to one new Western publication, a lower part of the periscope was not stationery, but it rotated in 180° range (there had been already known artillery Goertz panoramic sights with stationery lower part and crank-operated rotating prism, but they were complicated, one-eye, and apparently slower in area scanning and having narrower field of view). Gundlach periscope acted like a simple rotating periscope to look forward and sideward, what demanded turning head to the sides, but thanks to an additional prism extending down, the commander did not have to turn his head around the periscope to scan the area behind him. It had a 54° field of view. A patent was sold to Vickers-Armstrong firm before the war, and the reversible periscope became a standard in later allied tanks, including Soviet ones.

An engine was PZInż. 235 (Saurer VBLDb), Diesel, 6-cylinder inline vertical, water-cooled, capacity: 8550 cm³, 110 hp at 1800 rpm, cylinder bore x stroke: 110 x 150 mm.

The engine was placed centrally in a rear compartment. Two vertical water radiators with fans were placed on both sides of the engine - the air was drawn by two grills in forward part of a horizontal plate over the engine compartment, and flew out through two holes in a rear part of this plate. In early series it also flew out through blinds in rear doors. The rear compartment had two big doors in a rear wall, a small hatch above the engine, two small inspection hatches in side plates and two hatches in a wall separating engine and combat compartments. The fuel tank 110 l was placed in forward part of the hull, to the left (earlier publications claimed, that there was an additional 20 l tank, but it was suggested, that it was meant for radiator coolant in fact[10]).

Transmission: a dry multi-disc main clutch, a drive shaft in the combat compartment (under a cover). A mechanical gearbox with 4 gears forward, 1 reverse. Side clutches with band brakes, operated by levers.

Suspension: a drive sprocket in the front, an idler at the rear. The tank had a modified patented Vickers paired bogie-type suspension: on either side two units of two bogies with two double wheels each, sprung by cantilever leaf springs. Each suspension unit pivoted on its own axle.. In early prototypes only there were tested welded rocker arms, but eventually the tanks had cast rocker arms, like in Vickers. Comparing to original Vickers, suspension units had added lever below leaf springs, joining a body of the suspension unit with a bogie, decreasing forces acting against springs. A loose end of springs slid upon the lever, acting as a kind of a shock absorber All double roadwheels were the same, steel, rubber rimmed (on contrary to the Vickers, in which the last pair was steel only). One track had 109 links. Track width was 268 cm, track ground length: 2700(?) cm, distance between tracks' centres: 2028 mm. Four return rollers were on each side. Weight distribution on suspension sets was 4540 kg on the front and 5325 kg on the rear set.

From 1938, some single-turret tanks were equipped with a Polish radio N2/C - they were battalion, company and platoon commanders. The radio utilized a short whip receiver aerial on a turret niche's roof, and 6 m high transmitter aerial of a bamboo stick, mounted to the niche's left side. Probably it was made of two 3.5 m and 2.5 m parts, like in a cart-mounted version. Both were carried over a left fender, apparently with no special frame, and had to be erected manually. With 6 m aerial, it had range of 10 km for voice transmission and 25 km for Morse code (probably it was used only when stationery, like in transportable version). With shorter aerials, it had range up to 8 or 5 km for voice transmission. According to some publications, platoon commanders had receivers only[10], but it does not seem confirmed. Tanks with radios were also fitted with an intercom for the crew, who were equipped with new type helmets with integral headphones. Only 38 N2/C radio sets were produced for armoured weapons by the war, though not all were mounted in 7TP tanks. Several twin-turret tanks had received a radio earlier (probably older RKB/C). In a transport position, its pole aerial was carried horizontally, on two high struts between the turrets. According to memoirs, radio communication in 7TP tanks worked well, although its presence was limited to commanding vehicles – the rest of tanks had to follow the commander and watch signal flags.

In 1936, there was a standard camouflage scheme introduced for Polish vehicles. It consisted of irregular patches of greyish sand and dark brown over a base color of olive-green. The patches were airbrushed, with soft transitions, their shapes were mainly horizontal. There was not any standard pattern of patches. An interior was painted sand, including hatches. Some documents are lacking, but the camouflage was introduced by Technical Requirements for paints Nr. 4055 of 18 March 1936.

|

| 7TP tanks in standard camouflage (upper drawing by Adam Jońca) (drawings are in a different technique, in fact both should look similar to the lower one |

|

Initially, by 1936, twin-turret prototypes were painted in older camouflage scheme used, also called the "Japanese" one in Poland. Traditional publications claimed, that it consisted of patches in bright yellowish sand, dark green and dark brown, separated with thin black stripes. However, recent publications suggest, that the colours rather were yellowish sand, olive green and light blue-grey (read more on a page on tankettes).

Specifications of single turret variant [twin turret, if different]:

| Crew | 3 |

| Combat weight | 9,900 kg [9,400 kg] |

| Length | about 4600 mm [4750 mm with old muffler] |

| Width | 2400 mm |

| Height max. | 2273 mm [2181 mm] |

| Height to turret's roof | 2150 mm (Soviet measurements) |

| Track width | 268 mm |

| Tracks centers' spacing | 2028 mm |

| Track ground length | 2.7 m? (106.3 in)? |

| Ground clearance | 376 mm |

| Max. road speed | 32 km/h |

| Road / terrain range | 150 / 130 km (Soviet measurements: 195/130 km) |

| Ground pressure | 0.58 - 0.6 kg/cm2 |

| Fuel consumption | 80 - 100 litres /100 km |

| Wading depth | 1 m |

| Max. steepness | 35° |

| Crossing ditches | 1.8 m |

| Weight to power ratio | 11.1 HP/ton |

| Ground pressure | 0.6 kg/cm² |

| Fuel consumption (road - off-road) | 80 - 100 litres/100 km (Soviet measurements 57 - 85 l/100 km) |

Models of light tanks 7TP. Links lead to Scalemates service. You can share your comments on the models.

1/72:

1/76:

1/35:

Notes:

1. Assessing Polish capabilities, one should remember, that Poland was partitioned and occupied for over a century before World War I, and (unlike in Czechoslovakia) none of occupants was eager to place its machine or arms industry there. As a result, it had relatively weak industrial base at the moment of regaining independence. Moreover, after the war, priorities were to defend borders and rebuild and unify the country, with a tight budget. So, a choice of engines produced in the country was limited. The same factors also had an influence on a development and production of Polish tanks and other weapons.

2. There were only 22 sets of turrets removed from Vickers tanks, so they could not be mounted on two prototypes and 22 serial tanks (according to Magnuski, even 24 serial tanks). Moreover, two turrets were destroyed during shooting trials in 1934. Additional twin turrets might have been made of mild steel, for prototypes and possibly two training tanks. There is no information, that armoured turrets for a twin-turret variant were produced in Poland, and it would not even be reasonable, being only temporary solution – however, it can't be excluded. It is not confirmed, that any twin-turret tanks were rebuilt to single-turret (apart from the prototype, and unfinnished tanks), what is suggested in some publications.

3. The first publication researching 7TP orders and production in detail, resulting in a number of 132 serial tanks, was an article by Janusz Magnuski in "Nowa Technika Wojskowa" nr 12/1996 [2]. Earlier publications often quoted bigger numbers of tanks, without details. There are some doubts as for relaibility of peculiar numbers, though. Recently there appeared a series of articles on the 7TP by Karol Rudy, however they only partially cover the subject of production, although an overall number is similar. The subject still waits for a thorough research and analysis of available documents, which sadly seem scarse.

4. Publications conflict in details as for numbers and dates of 7TP orders, and it is still not clear. Moreover, dates of establishing orders and of formal orders might differ, what causes further confusion. J. Magnuski claimed, that there were 16 tanks ordered as twin-turret on 7 February 1936 (order no. 3/36-37/37/Panc), two of which eventually completed as twin-turret and 14 as single-turret, then 18 tanks were ordered in 1937, and he quoted serial numbers [2,7]. This version was repeated in more recent booklet by P. Rozdżestwieński [10]. K. Rudy however claims in new articles, that there were 18 tanks ordered in 1936 (FY 1936/37), and then 16 in 1937 (FY 1937/38), all completed as single-turret [4, 6]. Both theories differ in a resulting number of series-built twin-turret tanks - 24 or 22, for a total number. It might be noted, that L. Komuda wrote in an old booklet [9], that first came an order for 16 tanks on 17 February 1936, "probably enhanced to 18".

5. Numbers of 108 single-turret (97+11) and 24 twin-turret series tanks appear correct, provided, that J.Magnuski gave correct breakdown on single- and twin-turret tanks on 15 August 1939 (97 and 24 respectively, not counting prototypes), and correct information about producing two tanks of the second batch as twin-turret. They also agree with a total number of produced tanks. It is however unclear, if any tanks apart from the first series of 22 were really built as twin-turret, which would not be reasonable in a view of the tank's planned armament, and lack of spare turrets (see note 2). There is one more unclear issue, since in addition to 121 series tanks in units on that date (plus 2 prototypes), there was one experimental tank no.1766 with CT1D engine in the Technical Research Bureau (BBT BP), and it should be one of series tanks.

Sources:

1. Janusz Magnuski, Czołg lekki 7TP, "Militaria" Vol.1 No.5, 1996

2. Janusz Magnuski, Produkcja czołgów 7TP, 1935-1939 r., "Nowa Technika Wojskowa" nr 12/1996

3. Rajmund Szubański, Polska broń pancerna w 1939 roku; Warsaw 2004

4. Karol Rudy, O czołgu polskim raz jeszcze, "Poligon" nr 1/2010

5. Karol Rudy, 7TP - nowoczesny czy nie? [7TP - modern or not?], "Poligon" nr 6/2011

6. Karol Rudy, Czołg 7TP - na miarę skromnych możliwości, "Technika Wojskowa Historia" nr 5/2013

7. Janusz Magnuski, Rajmund Szubański, Janusz Ledwoch, 7TP vol.II, Wydawnictwo Militaria, Warszawa 2009

8. Andrzej Wszendyrówny, Marcin Wodejko: Czołg 7TP w dokumentach Centralnego Archiwum Wojskowego, "Do Broni" nr 1/2009

9. Leszek Komuda, Polski czołg lekki 7TP, Typy Broni i Uzbrojenia No.21, Warsaw, 1973

10. Paweł Rozdżestwieński, Czołg lekki 7TP, Wielki Leksykon Uzbrojenia Wrzesień 1939, No.1, Warsaw, 2012

11. Mariusz Zimny, Udział 1 Batalionu Czołgów Lekkich w walkach o Głowaczów 10 września 1939, Rocznik Archiwalno-Historyczny CAW

12. Mariusz Zimny, Zniszczenie części 2 Batalionu Czołgów Lekkich pod dowództwem kpt. Józefa Rejmana we wrześniu 1939 w relacjach uczestników walk , Rocznik Archiwalno-Historyczny CAW

13. Relacje o działaniach czołgów 7TP w kampanii wrześniowej, Rocznik Archiwalno-Historyczny CAW

Update history:

Main page – Polish armour – Polish artillery – Steel Panthers – Links

You can mail me with question or comments - corrections or photographs are welcome

All photos and pictures remain the property of their owners. They are published in non-commercial educational and research purpose.

Text copyright to Michal Derela, © 2015-2024